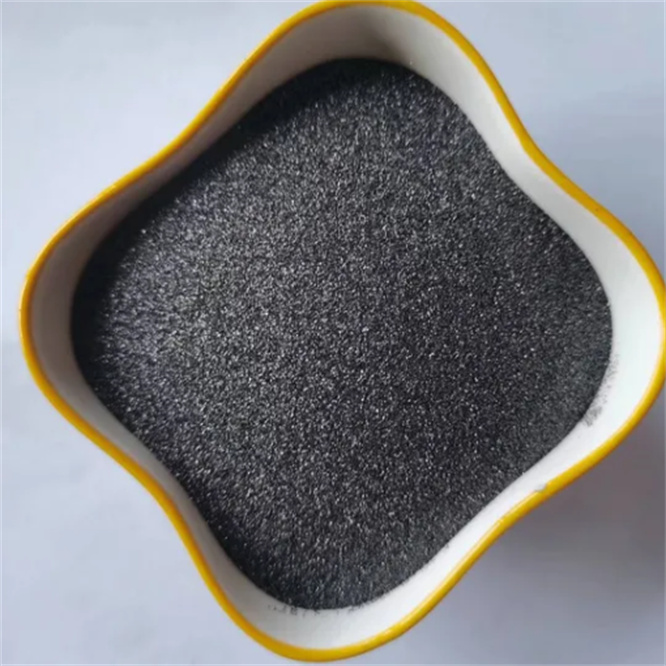

Black Boron Carbide Micro-Powder for Manufacturing Ceramic Products

Boron carbide is hard black with glossy crystals. Hardness is lower than industrial diamond, but higher than silicon carbide. It is less vulnerable than most pottery. It has a large thermal neutron capture cross section. Strong resistance to chemistry. The erosion of hydrogen fluoride and nitric acid. Soluble in molten base, insoluble in water and acid.

leixiang2@hbleixiang.com leixiang3@hbleixiang.com

Basic Info.

Boron carbide is hard black with glossy crystals. Hardness is lower than industrial diamond, but higher than silicon carbide. It is less vulnerable than most pottery. It has a large thermal neutron capture cross section. Strong resistance to chemistry. The erosion of hydrogen fluoride and nitric acid. Soluble in molten base, insoluble in water and acid.

Boron Carbide Powder (B4C) a black crystal powder, is one of the hardest Man-Made materials. Its hardness with Mohs hardness 9.36 and microscopic hardness 5400-6300kg/mm2 is only near upon diamond. Its density is 2.52g/cm3 and melting point is 2450ºC. It has excellent abrasion resistance and large neutron-absorbing cross section. The boron carbide possesses properties of endurance hi/low temperature, no reaction with either acids or alkalis, high grinding efficiency, no magnetism. It is a good replacement of diamond. Boron carbide also possesses the special properties of light quality, neutron absorbing, semi-conductivity, etc., so it is widely used in machinery, electronics, instrumentation, metallurgy, national defense, armed forces, nuclear, aviation industry, and also used as abrasives, classic refractory and specific welding materials, human protection materials and so on.

Our factory

“Strength builds the foundation, and excellent services reach all over the world.” Create win-win situation with customers

Leave A Message

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.